Non-Optical Brinell Hardness Measurement Using Instrumented Indentation Method

The Brinell hardness test is a representative method for quickly evaluating the strength of materials. Changes in hardness values serve as important indicators for predicting material property changes or remaining service life. Traditional Brinell hardness measurement requires optical measurement of the indentation diameter, necessitating specializedequipment and time.

However, non-optical Brinell hardness measurement using the Instrumented Indentation Method enables more efficient and precise hardness evaluation through load and depth data. By analyzing the load-depth curve, the indentation depth is corrected, and hardness is calculated, resulting in greater accuracy.

Principle of the Brinell Hardness Test

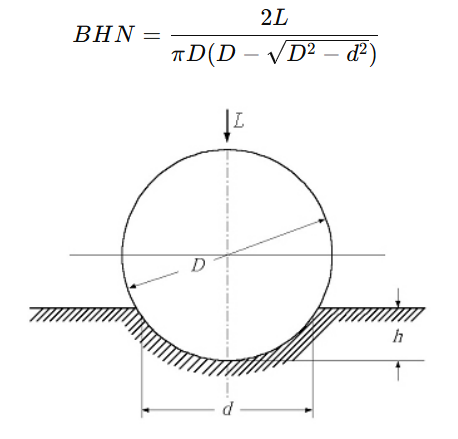

Brinell hardness is evaluated by applying a constant load to a specimen using a spherical indenter and measuring the size of the indentation left by the indenter. As shown in Figure 1, when a spherical indenter with a diameter 𝐷 (mm) applies a load

𝐿 (kgf) to the specimen, a permanent indentation is formed on the surface of the specimen. The diameter 𝑑 (mm) of this indentation is measured to calculate the Brinell hardness. The Brinell hardness formula is as follows:

Figure 1. Schematic of the Brinell Hardness Test

Limitations of Traditional Methods: Optical Observation

In traditional Brinell hardness tests, the diameter of the indentation must be measured optically, a process that is time-consuming and may require high-resolution equipment. Additionally, measurement errors can arise due to the specimen’s surface condition or the shape of the indentation. These issues highlight the need for a more efficient and accurate measurement method.

Introduction of Instrumented Indentation Method

The Instrumented Indentation Method analyzes the load-depth curve to estimate the size of the indentation without the need for optical observation. This method directly measures the indentation depth while applying the load, eliminating the inconvenience of optical measurements and improving test efficiency. The load-depth curve represents the relationship between load and indentation depth during the indentation of the specimen.

However, this curve alone cannot accurately estimate the indentation depth due to simultaneous elastic and plastic deformation of the material.

Elastic and Plastic Deformation Correction

To accurately estimate the indentation depth from the load-depth curve, the material’s deformation behavior must be precisely analyzed and corrected. The following correction methods are used:

Elastic Deformation (hd)

The temporary deformation that occurs when the load is applied can be calculated using the maximum load 𝐿max, the initial tangent slope 𝑆, and the material constant 𝜒.

Plastic Deformation (hp)

Plastic deformation occurs when the indenter causes permanent deformation in the material. To compensate for this, the material's strain hardening index 𝑛 and deformation factor (ℎmax/𝑅) are used, where 𝑅 is the radius of the spherical indenter. By correcting these two types of deformation, the final accurate indentation depth ℎ𝑐 can be calculated.

Hardness Calculation

Once the accurate indentation depth is determined, the diameter of the indentation can be calculated based on this depth. Using the shape of the spherical indenter and the corrected contact depth, the final Brinell hardness can be calculated. This method allows hardness evaluation by directly analyzing the load-depth curve through Instrumented Indentation Testing, providing an advantage of obtaining precise Brinell hardness without optical observation.

Summary

Non-optical Brinell hardness measurement using the Instrumented Indentation Method offers high accuracy while reducing time and cost compared to traditional optical measurement methods. By utilizing precise indentation depth estimation and correction techniques through load-depth curve analysis, more reliable hardness measurement results can be achieved. This allows for efficient monitoring of material property changes and quality control across various industries.

Directions

Directions