Resources

Instrumented Indentation Test (IIT)

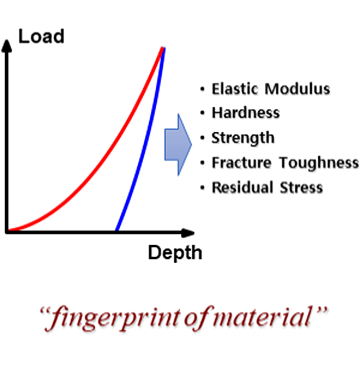

IIT accurately evaluates a wide range of mechanical properties, such as tensile characteristics, fracture toughness, and residual stress through the load-displacement curve.

IIT minimizes surface damage, making it suitable for large structures and expensive specimens. Any indentations left can be removed by polishing, allowing non-destructive testing with no practical damage.

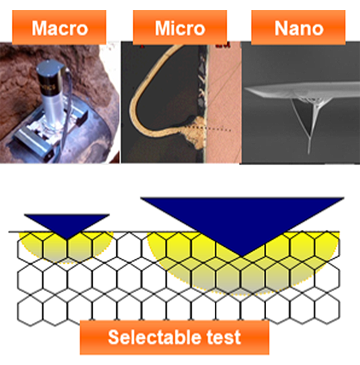

IIT provides high spatial resolution to analyze localized mechanical properties, allowing detailed evaluation of microstructural changes or weak points by mapping material characteristics.

IIT is effective for nanoscale and microscale testing, making it ideal for analyzing thin films or small specimens, as well as for research and technological applications involving nanomaterials.

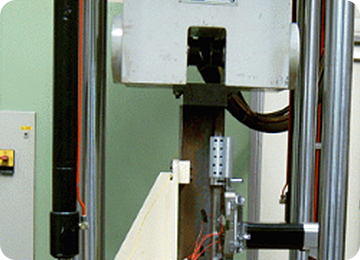

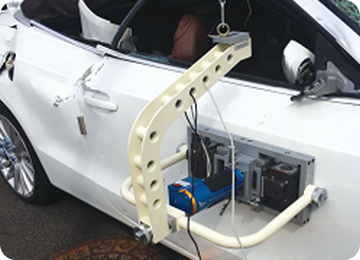

IIT is ideal for large-scale structures such as energy pipelines, power plants, and petrochemical facilities, where it can non-destructively measure mechanical properties on-site and provide valuable data without causing damage.

IIT can precisely analyze the mechanical properties of small specimens and thin films down to the nanoscale, making it highly suitable for advanced industries such as 3D printing materials, nanocoatings, and electronic components.

IIT is useful for assessing localized property variations and residual stress in areas such as weld joints, coating layers, and 3D-printed materials, helping to evaluate structural safety and analyze fine defects.

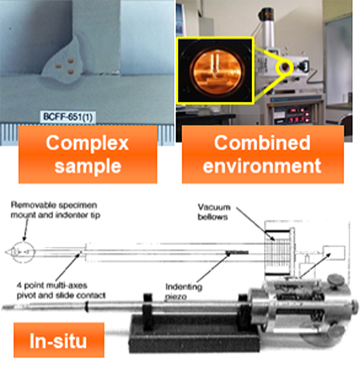

IIT can be used to non-destructively evaluate material properties in hazardous environments, such as high-temperature, high-pressure, or corrosive media, making it effective even when specimen sampling is difficult.

IIT offers faster and simpler testing compared to traditional methods, contributing to process optimization and increased productivity in applications such as smartphone drop tests and aircraft component reliability assessments.

IIT can analyzesubtle changes in mechanical propertiesand residual stress states that occur during material processing and product manufacturing, helping optimize processes and improve product quality.

Directions

Directions