Resources

Adhesion Strength

Weak Adhesion: If the adhesion strength is weak, the film and substrate respond independently to the indentation load, causing a strain discontinuity at the interface. This results in a sharp change in the load-displacement curve.

Weak Adhesion: If the adhesion strength is weak, the film and substrate respond independently to the indentation load, causing a strain discontinuity at the interface. This results in a sharp change in the load-displacement curve.

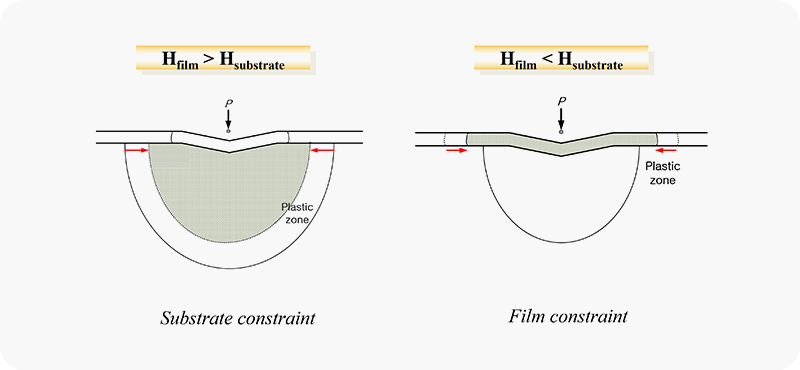

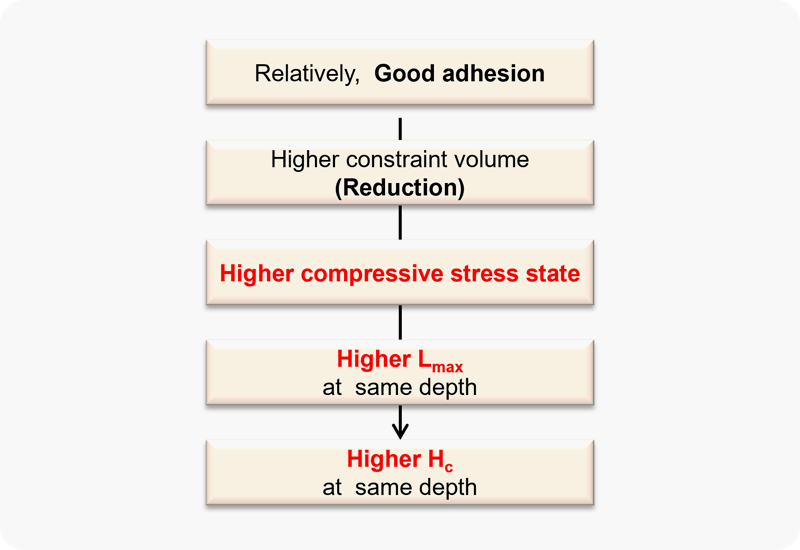

Strong Adhesion: With strong adhesion, the strain is continuously distributed, and additional plastic deformation energy is required, increasing the composite’s hardness. Strong adhesion induces compressive stress at the interface, as the film's deformation is constrained by the substrate.

Strong Adhesion: With strong adhesion, the strain is continuously distributed, and additional plastic deformation energy is required, increasing the composite’s hardness. Strong adhesion induces compressive stress at the interface, as the film's deformation is constrained by the substrate.

Compressive stress at the film-substrate boundary is an important indicator of adhesion strength. High compressive stress indicates a strong mechanical or chemical bond, reducing the likelihood of delamination and strengthening structural integrity. The greater the adhesion strength, the higher the load required to achieve the same indentation depth, serving as a criterion for evaluating adhesion strength in indentation testing.

The load required to achieve a set indentation depth serves as the basis for evaluating composite hardness and adhesion strength. A composite with strong adhesion requires a higher load to achieve the same indentation depth, which can be used to quantify the adhesion strength.

Hard Films: The adhesion strength of hard films is assessed using the scratch test, and when a soft substrate is coated with a thin film, the results show trends similar to those of the IIT method.

Hard Films: The adhesion strength of hard films is assessed using the scratch test, and when a soft substrate is coated with a thin film, the results show trends similar to those of the IIT method.

Soft Films: For soft films, the film may deform easily during the scratch test, so a pull-off test can be conducted alongside the indentation test to evaluate adhesion strength. The results of these tests also exhibit similar trends.

Soft Films: For soft films, the film may deform easily during the scratch test, so a pull-off test can be conducted alongside the indentation test to evaluate adhesion strength. The results of these tests also exhibit similar trends.

Adhesion strength can be evaluated using a single indentation test without the need for additional equipment.

The indentation load is precisely adjusted according to changes in adhesion strength, providing reproducible results.

Unlike the scratch test, a single indentation can evaluate the adhesion strength at specific points, and mapping can reveal the distribution of adhesion strength across different film locations.

The method can be applied to both hard and soft films.

Indentation load can be adjusted locally, allowing the test to be performed without damaging the overall film condition.

The method allows for real-time evaluation of adhesion strength changes during the manufacturing process.

Directions

Directions